As regular Measurement Technology NW followers may know, back in November 2008 MTNW and a group that included Midwest Research Institute, Boston Dynamics, Smith Carter CUH2A, and HHI Corporation were chosen by the US Army to design and build “IPEMS” (Individual Protection Ensemble Mannequin System).

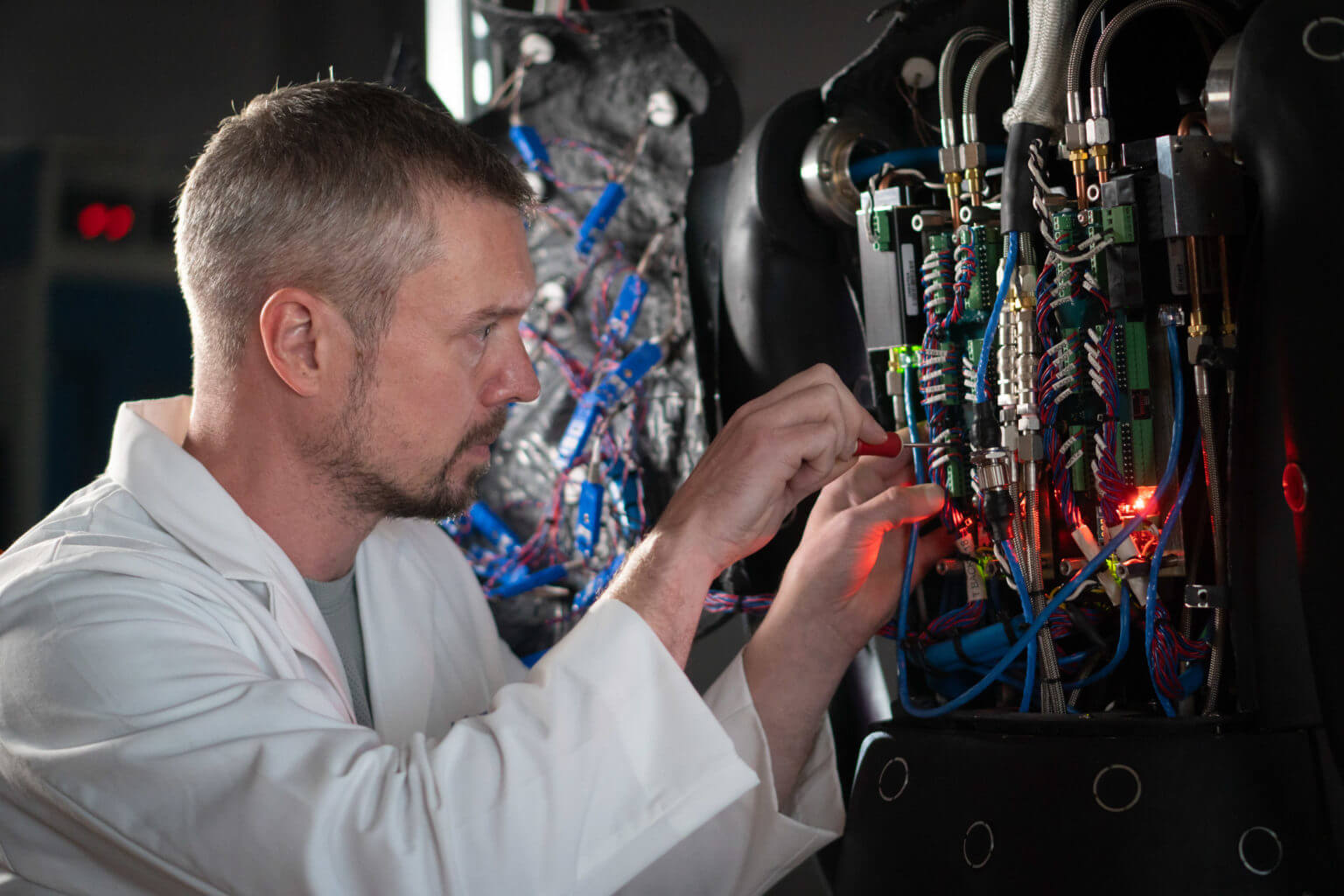

This project includes state-of-the-art chemical testing facilities and a first-of-its-kind robotic thermal mannequin to perform high-resolution testing of protective clothing and equipment under live chemical exposure conditions.

The IPEMS mannequin will be a freestanding, self-balancing robot that will simulate human physiology for realistic tests of protective equipment in a controlled environment. Measurement Technology NW’s role is to develop IPEMS’s skin surface segments and thermal control systems, while other partnering companies developed the robotic mannequin’s internal structure.

Integrating full-function thermal, perspiration, and chemical sensing controls into a 50th percentile body form, while also fitting it over an internal robotic structure capable of ranges of movement far beyond that of existing mannequin systems, presented some significant challenges. Adding more complexity to this challenge was the need for sealed skin surfaces and joints to prevent chemical agent contamination, while still allowing internal access for service and repairs. The IPEMS mannequin design that emerged from Phase 1 – the design phase – included a body surface segmented into 17 separate hard-shell regions (14 independent thermal zones), each with sweating capability and chemical sensing ports.

Overall, Phase 1 was a successful effort. Phase 2 – the fabrication phase – will include first-article build up of a mannequin shell region and joint sleeve. After decontamination testing and safety/operational procedures are finalized, work will begin on building the first IPEMS mannequin.