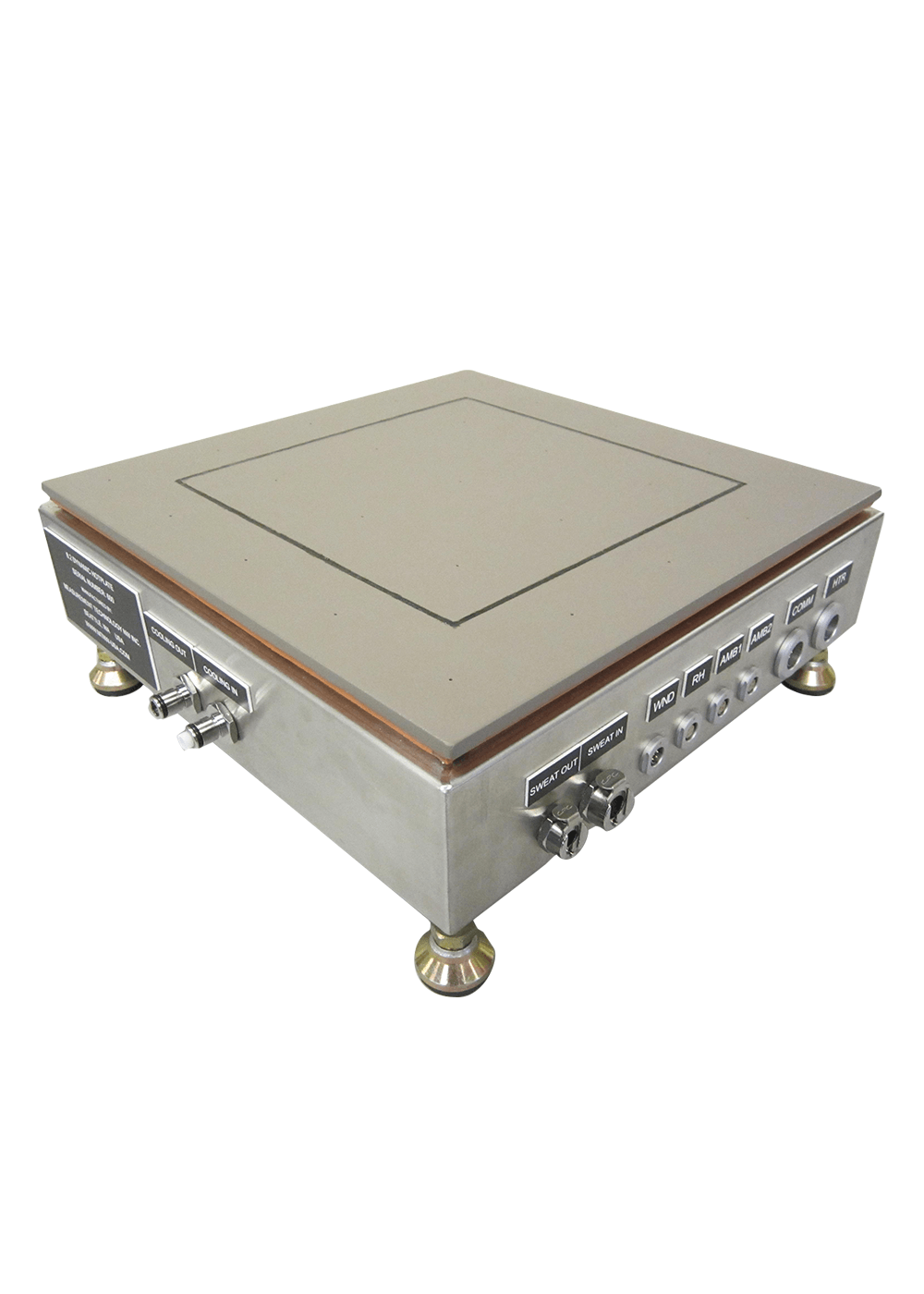

Dynamic Hotplate System

Test prototype swatches for positive and negative heat-flux measurements.

Accurate, repeatable measurements in non-traditional environments

The Dynamic Hotplate System (DHS) is an advanced sweating guarded hotplate that provides accurate, repeatable measurements of the thermal resistance (Rct) and vapor permeability (Ret) of textiles in conditions that are not steady-state, and it represents the next big step in hotplate technology. The Dynamic Hotplate is designed to handle test situations involving positive or negative heat flux, and it excels when evaluating textiles in transient environments.

The sensor technology used in our Dynamic Hotplate System generates instantaneous surface heat-flux measurements, and as a result the DHS hotplate can be used for PCM samples, tests of heated fabrics and pads, or for textile testing under sustained solar loads and elevated ambient temperatures up to 50°C.

The next step in sweating hotplate technology

The hotplate system features a microprocessor-controlled fluid supply system which precisely regulates flow volume for any sample. Two sizes are available. The DHS–8.2 model features an 8” (20.3 cm) test plate with 2” (5 cm) guard. An integrated climate control chamber can be added, as well as interchangeable “dynamic” DHS and “traditional” SGHP test plates, for installations where textile research programs also require compliance with ISO 11092 and ISO 13029.

Resources

Standards

Learn more about test standards

Parts store

Order parts direct from online

Service plans

Find a service plan